It is suitable for evaluating the fire resistance of products such as fire doors installed at the openings of vertical partition members, fire shutter assemblies, fire bricks, fire glass, fire partition walls and fire windows.

1. Scope of application:

1.1 It is suitable for evaluating the fire resistance of products such as fire doors installed at the openings of vertical partition members, fire shutter assemblies, fire bricks, fire glass, fire partition walls and fire windows.

2. Compliant standards:

2.1 Comply with GB/T7633-2008 "Fire resistance test—doors and shutter assemblies", ISO 3008-2007 "Fire resistance test—door and shutter assemblies" and ISO 834-1:1999 "Fire-resistant test—Elements of building construction—Part 1: General Requirements".

ASTM E119, ISO 3008, ASTM E814, ASTM E1966, BS 476, BS EN 1363, BS EN 1366, BS EN 1634-1, BS ISO 3009, UL 94, UL 263, UL 1479, UL 1709, UL 2079

4. Main technical parameters:

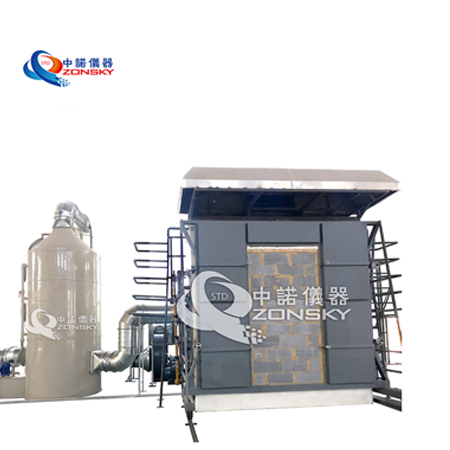

4.1 Instrument composition: refractory test furnace, gas flow measurement system, temperature measurement system, pressure measurement and control system.

4.2 Refractory test furnace: It is a vertical test furnace with inner dimensions of 3M(length)x3M(height)x1.25M(depth).

4.3 Furnace body structure: a steel structure frame is used, and the furnace wall is built with refractory bricks in the middle of the steel structure frame. The outer side is wrapped with color steel, the thickness of the furnace lining material is 50mm, and the test temperature in the furnace is as high as 1250℃. The furnace is produced, installed and tested in our ZONSKY. According to the function preset by our client, it is disassembled into parts suitable for reassembly and packed into a trailer for transportation.

4.4 Burners: 10 high-speed burners are embedded in the furnace walls on both sides(5 on each side). They provide the heat required to heat up the furnace.

4.5 Flue gas collection:

4.5.1 A conical flue gas collection tower is installed on the top of the furnace to collect the flue gas leaked during the sample test in front of the furnace.

4.5.2 Fan power: 3kw, a powerful smoking fan.

4.5.3 Pipeline of collecting gas: it uses a pipeline with a diameter of 300mm, which is directly connected to the pressure release system.

4.5.4 Conical collection tower: 2.0mm thick, USU304 stainless steel plate.

4.6 Temperature measurement system

4.7 Computer Control System

4.8 Flue gas purification system

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now