The flame retardant grade of plastics decreases step by step from V-0, V-1, V-2 to HB. HB UL94 and CSA C22 2NO 017 are the lowest flame retardant ratings in the standard. The U.S. American flame retardant material standard is ANSI/UL-94-1985 standard UL94 test has five kinds:

1. Horizontal burning test of 94HB class

2. 94V-0 94V-1 94V-2 level vertical burning test

3.94 5-V level vertical burning test

4. Flame spread index test with radiant panels

5. Vertical burning test of 94VIM-0 94VIM-1 94VIM-2 level

Among them, the horizontal burning test method of plastic grade B:

Experimental sample: Use a small strip sample with a length of 127mm, a width, a maximum thickness, and the smallest size.

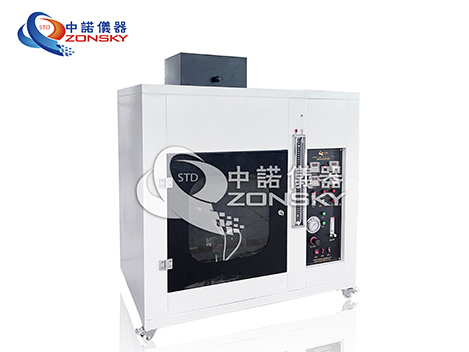

Test conditions: carried out in a non-ventilated test chamber.

Evaluation method: For materials rated as 94HB grade, the burning speed on the gauge length is not more than 38lnm/min when the thickness of the sample is 200mm. Or when the thickness of the sample is less than 38 lnm/min, or before reaching the 102mm mark, the burning must be stopped.

94V-1 94V-2 level vertical burning test method:

Experimental sample: This test uses a small strip sample with a length of 127mm and a maximum thickness of 127mm.

Test conditions: carried out in a non-ventilated test chamber.

Evaluation method: For materials rated as 94HB grade, the burning speed on the gauge length is not more than 38lnm/min when the thickness of the sample is 200mm. Or when the thickness of the sample is less than 38 lnm/min, or before reaching the 102mm mark, the burning must be stopped.

Evaluation method: The upper end (place) of the sample is clamped by the clamp on the bracket, and the longitudinal axis of the sample is kept vertical. The lower end of the sample is 305mm from the lamp nozzle to the surface of the dry absorbent cotton, and the Bunsen burner is ignited and adjusted to produce a blue flame with a height of 19mm. Place the Bunsen burner flame on the lower end of the sample, ignite for 10s and then remove the flame (at least 152mm away from the sample), and record the flaming burning time of the sample. If the flame of the sample goes out 30s after the flame is removed, the Bunsen burner must be moved under the sample again and re-ignited. The sample is ignited for 10s and then the Bunsen burner flame is removed again, and the flame burning time and flameless burning time of the sample are recorded.

If there are smoke particles in the molten drop of the sample, let it fall on the absorbent cotton 305mm below the sample to see if it ignites the absorbent cotton. If the absorbent cotton catches fire, it should be factored into the rating. The specific grading indicators are as follows:

1. Ten ignition times always have a maximum burning time (S)

2. Individuals have a maximum burning time (s)

3. Flameless burning time (s)

4. Flame droplet 94V-0 50 10 30 without 94V-1 250 30 60 without 94V-2 250 30 60 is only allowed to burn for a short time.

Note: The vertical burning test in UL94 is based on the burning time of the sample. According to the test results such as whether the molten droplets ignite the absorbent cotton, the polymer material is rated as V-2, V-1, V-0 and 5-V. Among them, the V-2 grade is the lowest flame-retardant grade, and the 5-V grade is the highest flame-retardant grade.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now