Ensuring the structural integrity and safety of buildings is of utmost importance in the construction industry. To achieve this, various testing methods and equipment are employed to evaluate the performance and reliability of building components. This essay aims to explore the three basic Building Component Testing Equipment commonly used in the industry, highlighting their significance in ensuring quality construction.

1. Load Testing Equipment:

Load Testing Equipment plays a fundamental role in assessing the strength and durability of building components, such as beams, columns, and slabs. Load testing helps determine how the components respond to external forces, simulating real-life conditions to gauge their capacity to bear loads. Some common load testing equipment includes:

a. Hydraulic Jacks and Load Cells: Hydraulic jacks are used to apply controlled and measured loads, replicating the forces that a building component may encounter during its lifecycle. Load cells, on the other hand, are sensors that measure and monitor the applied load, providing precise data for evaluation.

b. Universal Testing Machine (UTM): UTMs are versatile equipment capable of testing various building materials, including concrete, metals, and composites. They can perform tension, compression, and bending tests, providing essential information on the strength and elasticity of building components.

c. Deflection and Strain Gauges: These gauges measure the deflection and strain in building components subjected to load. They help determine the structural behavior, deformation, and durability of the materials under stress, offering crucial insights into their performance.

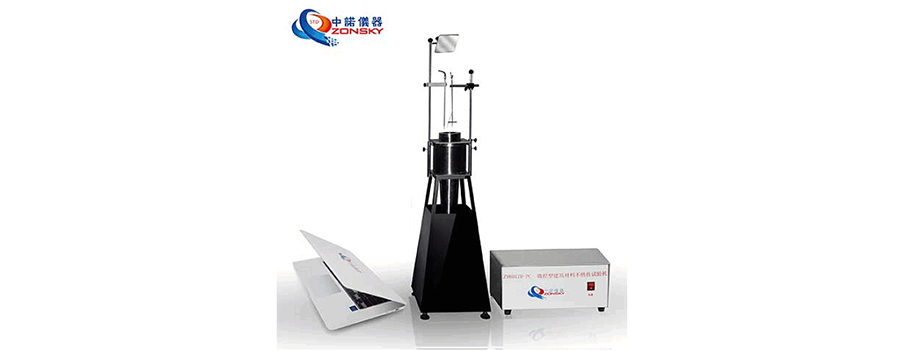

2.Fire Testing Equipment:

Fire testing equipment is employed to evaluate the fire resistance and performance of building materials and assemblies. This testing ensures compliance with fire safety regulations and helps in the selection of suitable materials for specific applications, thus minimizing fire risks. Several key fire testing equipment include:

a. Furnace and Fire Testing Chambers: Furnaces and fire testing chambers recreate fire conditions, exposing building components to high temperatures and flames. These controlled environments mimic real-life scenarios and assess the behavior and reaction of materials to fire, including factors such as flame spread, smoke production, and heat release.

b. Thermocouples and Pyrometers: These instruments measure and monitor temperatures during fire testing. Thermocouples are small sensors that detect temperature changes, while pyrometers are non-contact devices used to measure high temperatures. Accurate temperature data aids in analyzing the fire resistance and performance properties of building components.

c. Smoke Density and Toxicity Testers: These testers evaluate the smoke density and toxicity emitted by building materials during combustion. Assessing these properties helps gauge the potential impact on occupant safety during a fire event and aids in material selection for fire-resistant designs.

3.Moisture Testing Equipment:

Moisture testing equipment assesses the moisture content and moisture-related properties of building components, such as concrete, wood, and insulation materials. Excessive moisture can lead to various issues, including mold growth, deterioration, and reduced structural performance. Key moisture testing equipment includes:

a. Moisture Meters: These handheld devices measure the moisture content within building materials. They employ different technologies, such as pin-type or pinless sensors, to detect and quantify moisture levels accurately. Moisture meters aid in identifying potential moisture problems and guide decisions regarding material suitability or necessary remedial actions.

b. Relative Humidity Probes: Relative humidity probes assess the moisture level and equilibrium conditions within the building envelope or enclosed spaces. These probes penetrate materials to measure relative humidity levels, helping to prevent issues like condensation, mold, and material degradation.

c. Infrared Thermal Imaging Cameras: These cameras utilize infrared technology to visualize temperature variations on the surface of building components. By detecting temperature differences, they can identify areas of potential moisture intrusion, thermal bridging, or insulation deficiencies, allowing for timely interventions and improved building performance.

Building component testing equipment forms a cornerstone in ensuring the quality, reliability, and safety of construction projects. Load testing equipment helps evaluate structural capacity, fire testing equipment assesses fire resistance, while moisture testing equipment aids in mitigating moisture-related issues. By employing these three basic categories of testing equipment, construction professionals can make informed decisions, select suitable materials, and ensure compliance with relevant standards and regulations. Ultimately, the utilization of building component testing equipment fosters the creation of robust and durable structures, enhancing both the integrity and longevity of buildings.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now