In the dynamic telecommunications world where connectivity is critical, the reliability of fiber optic cables is of paramount importance. Fiber optic cable bend testing machines play a vital role in ensuring the durability and performance of fiber optic cables, the lifeblood of our connected world. The significance of repeated bending tests:

The significance of repeated bending tests:

Fiber optic cables are responsible for transmitting large amounts of data via light pulses and must withstand a variety of environmental and mechanical stresses. A key factor is the cable's ability to withstand repeated bending without affecting signal integrity or structural integrity. Fiber optic cable repeated bend testing machines are essential tools for evaluating the bending stress resistance of fiber optic cables to ensure they meet industry standards and can withstand the challenges of installation and use.

Testing machine functions:

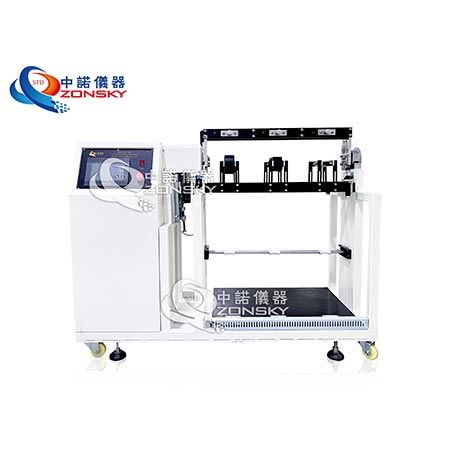

Optical cable repeated bend testing machines are designed to simulate real conditions and subject optical cables to repeated bending cycles. The machine performs a controlled, repetitive bending motion on the cable, simulating scenarios in which a cable may experience bending during installation, maintenance or natural environmental factors. The goal is to evaluate the cable's ability to withstand these stresses without causing signal degradation or physical damage.

Key features and components:

Bending Mechanism: The machine is equipped with a precision bending mechanism that enables controlled and repeatable bending cycles. Bending radius and speed can often be adjusted to simulate different installation scenarios.

Tension Control: To accurately replicate real-life conditions, the machine features a tension control system. This ensures that the cable is subjected to the appropriate level of tension during bending, allowing for a complete assessment of its performance.

Automatic cycle: Optical cable repetitive bend testing machines usually have an automatic cycle function, which allows for continuous, uninterrupted testing. This automation ensures consistent and reliable results over a large number of bending cycles.

Monitoring and data collection: Advanced testing machines are equipped with monitoring systems to track parameters such as insertion loss, return loss, and other related metrics. This data is critical for evaluating cable performance under repeated bending stress.

Test process:

Preparation: Prepare the optical cable to be tested and fix it on the testing machine. Proper fixation is critical to replicating real-life conditions.

Parameter adjustment: The operator adjusts parameters such as bending radius, speed, and tension control according to testing standards or specific requirements.

Test Start: The machine initiates a repetitive bending cycle that subjects the fiber optic cable to controlled stress. Loops last for a predetermined number of cycles, typically ranging from hundreds to thousands.

Data Analysis: Throughout the testing process, the machine monitors and collects data on various performance indicators. After testing, the collected data is analyzed to evaluate any changes in cable characteristics.

Industry standards and compliance:

Fiber optic cable bend testing machines adhere to industry standards and specifications set by organizations such as the International Electrotechnical Commission (IEC) and the Telecommunications Industry Association (TIA). Complying with these standards ensures that fiber optic cables tested on these machines meet stringent requirements for reliability and durability.

In the ever-evolving telecommunications field, the reliability of optical cables cannot be ignored. Fiber optic cable repeated bend testing machines play a key role in ensuring that these cables can withstand the challenges of real-world use. By subjecting them to controlled and repeatable bending stresses, these test machines help improve the robustness of communications infrastructure, enabling seamless connectivity in our connected world.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now