The textile industry relies on a wide range of fibers to produce fabrics with diverse properties and characteristics. To ensure the quality, durability, and safety of textiles, rigorous testing is essential. Textile fiber Testing Equipment plays a vital role in assessing the physical, mechanical, and performance attributes of textile fibers. This essay aims to provide an in-depth exploration of textile fiber Testing Equipment, highlighting its importance, key features, and applications.

1. Importance of Textile Fiber Testing:

Textile Fiber Testing Equipment is crucial for ensuring the consistency, quality, and performance of textile materials. By subjecting fibers to various tests, manufacturers can determine their suitability for specific applications. Accurate testing allows for compliance with industry standards, regulatory requirements, and consumer expectations. It assists textile producers in making informed decisions about fiber selection, blending, processing, and overall product quality control.

2. Fiber Identification:

One of the primary applications of textile fiber testing equipment is fiber identification. Different fiber types, such as cotton, wool, silk, polyester, or nylon, have distinct physical and chemical characteristics. Microscopes, burn tests, and chemical reagent tests are commonly used to identify fibers based on their appearance, melting behavior, reaction to certain chemicals, or microscopic features. Accurate fiber identification ensures the correct use and processing of textiles.

3. Fiber Length and Strength Analysis:

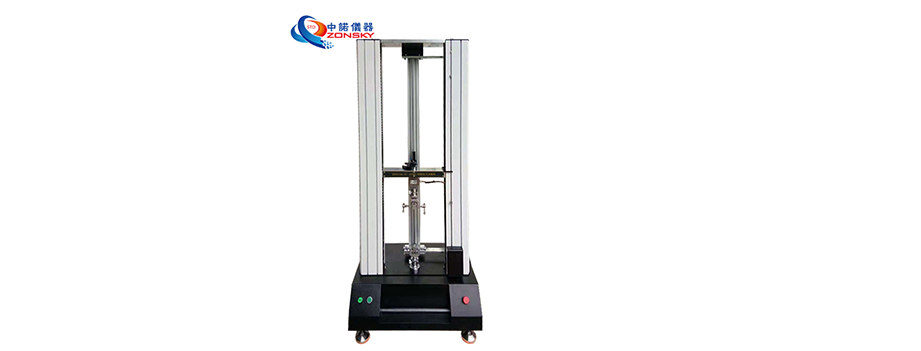

Fiber length and strength are critical factors in determining the quality and performance of textiles. Fiber testing equipment, such as fiber length analyzers and tensile testing machines, measures these properties with precision. Fiber length analyzers utilize optical or image-based methods to analyze the average fiber length and length distribution, providing insights into the spinning potential and end-use applications of fibers. Tensile testing machines assess the breaking strength, elongation, and elasticity of fibers, enabling manufacturers to ensure the desired mechanical properties of fabrics.

4. Fiber Fineness and Uniformity:

The fineness and uniformity of textile fibers significantly impact the fabric's appearance, texture, and comfort. Fiber fineness, expressed in terms of denier or tex, represents the thickness or diameter of individual fibers. Testing equipment, such as fiber fineness testers or diameter measurement devices, accurately measures this parameter. Additionally, instruments like the evenness tester assess the uniformity of fibers throughout a sample, detecting variation in thickness or diameter. These tests help manufacturers achieve consistent and high-quality fabrics.

5. Moisture Regain and Absorbency:

Textile fibers' moisture regain and absorbency properties are crucial for comfort, breathability, and performance in various applications. Moisture regain measures the ability of fibers to absorb and release moisture from the surrounding environment. Testing devices, such as moisture regain testers, use controlled humidity and temperature conditions to determine this property accurately. Water absorption tests assess the capacity of fibers to absorb and retain water, providing insights into their suitability for applications such as towels or medical textiles.

6. Color Fastness and Dyeability:

Color fastness and dyeability are important aspects of textile fiber testing. Color fastness refers to the resistance of fibers to fading or color transfer when exposed to various environmental factors such as light, washing, or rubbing. Testing equipment, including color fastness testers, simulates these conditions to evaluate fiber performance and ensure satisfactory color retention. Dyeability tests assess how well fibers accept and retain dyes, helping manufacturers achieve desired color vibrancy and intensity.

Conclusion:

Textile fiber testing equipment plays a vital role in ensuring the quality, performance, and durability of textile products. By accurately assessing fiber properties such as identification, length, strength, fineness, uniformity, moisture regain, absorbency, color fastness, and dyeability, manufacturers can make informed decisions regarding material selection, processing, and overall product quality control. The use of advanced testing equipment enhances the efficiency of textile production processes, compliance with industry standards, and customer satisfaction, ultimately contributing to the success of the textile industry as a whole.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now