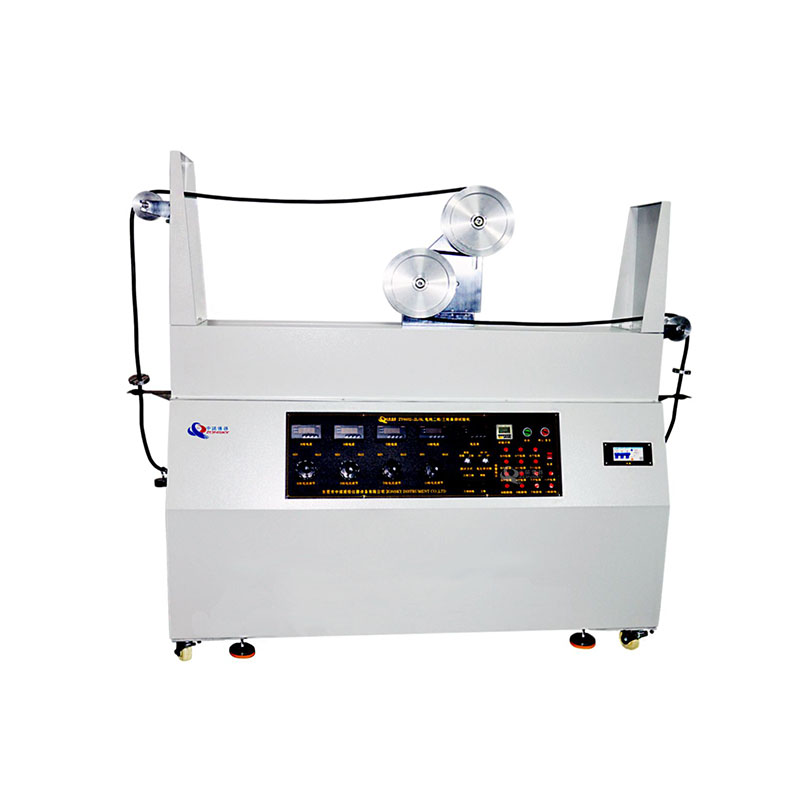

Flex Tester Machine Meet the standard requirements of UL 1581. After 15,000 reciprocating movements of the flexible cable used to detect rubber insulation and sheath, that is, 30,000 single-way movements, neither current interruption nor short circuit between conductors should occur.

1. Scope of application:

1.1 Two-wheel flexure test: After 15,000 reciprocating movements of the flexible cable used to detect rubber insulation and sheath, that is, 30,000 single-way movements, neither current interruption nor short circuit between conductors should occur. Three-wheel flexure test: During 1000 times of reciprocating movement, that is, 2000 times of one-way movement, there should be no open circuit of the conductor, no short circuit between the conductors, and no short circuit between the cable and the pulley (test equipment).

2. Compliant standards:

2.1 Meet the standard requirements of Section 3.1 of GB/T 5023.2-2008, Section 3.1 and Section 3.5 of GB/T 5013.2-2008 and UL 1581.

3. Main parameters:

3.1. Test station: 1 station, one sample is tested each time;

3.2. Winding mode: two pulleys/three pulleys;

3.3. Bending speed: 0.33 m/s for the second pulley and 0.1m/s for the third pulley;

3.4. Bending stroke: ≥1M;

3.5. Test current: adjustable from 0 to 35A;

3.6 Test voltage: two-core single-phase AC: 0-230V (adjustable), three-core three-phase AC: 0-400V (adjustable) 50HZ.

3.7 Test line type: It can detect two-core single-phase, two-core three-phase, three-core three-phase, three-core four-phase.

3.8 Hammer mass: two pulleys of 1.0kg, 1.5kg, 2.0kg, 2.5kg, 3.0kg, 3.5kg, and 4.0kg each. Three pulleys 14N, 21N, 28N each two. If you need other hammers, please consult us for custom-made.

3.9 Diameter of pulleys: two pieces each of φ80, φ120, φ160, and φ200 (mm), three pieces each of three pulleys φ40, φ45, and φ50 (mm), and the pulleys are semicircular grooved pulleys suitable for round cable detection. If you need to detect flat-bottomed grooved pulleys for flat cables, please consult us for custom-made.

3.10 Detection of fault shutdown: When the actual test sample conductor is open circuit, short circuit between conductors, short circuit between cable sample and pulley, and has broken wire indication, interphase short circuit indication, core and shell short circuit indication function.

3.11. Dimensions: length 188cm x width 53cm x height 150cm;

3.12. Power requirements: AC380 (±10%) V/50HZ.

4. Equipment structure:

4.1. The control panel is located right in front of the machine for easy observation and operation, and the power supply is located at the back of the machine.

4.2. The driving structure is concealed, the overall appearance is neat and beautiful, and it is easy to clean.

4.3. The pulley device is located on the top of the machine, and the pulley is a nut locking structure, which is convenient for users to replace the pulley to test different samples.

4.4. There are four universal casters at the bottom of the chassis for easy movement. During the test, press down the caster locks to fix the machine not to move.

5. Components, materials and functions:

5.1. Outer box material: The outer shell is made of high-quality (thickness 1.2mm) electrostatic steel plate, which is processed and formed by CNC machine tools.

5.2. Pulley material: high-quality aluminum with polished surface.

5.3. Weight material: 45# surface thickened electroplating treatment.

6. Mechanical drive system:

6.1. Taiwan DC geared motor + sprocket chain structure.

6.2. The relay control system is adopted, and all electronic components are domestic leading brands, which can better guarantee the performance and detection accuracy of the machine.

6.3. The equipment has the following safety protection devices: power overload, short circuit protection, control circuit overload protection.

7. Environmental conditions of use:

7.1. The ground is flat, well ventilated, free of flammable, explosive, corrosive gases and dust.

7.2. There is no strong electromagnetic radiation source nearby.

7.3. Ground bearing capacity of the venue: not less than 200kg/m2.

7.4. Appropriate maintenance space should be left around the equipment.

7.5. Temperature: 5℃~30℃.

7.6. Air pressure: 86 ~ 106kpa.

7.7. Allowable fluctuation range of voltage: 380V±10%.

7.8. Allowable fluctuation range of frequency: 50Hz±1%.

7.9. The user is required to configure a power switch of corresponding capacity for the equipment at the installation site, and this switch must be independent and dedicated to the use of this equipment.

7.10. When the equipment is not working, the ambient temperature should be kept within +0~45℃.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now