The test apparatus for the flame retardant test method of building materials is used for the determination of the flame retardant performance of building materials, mainly including two parts: burning shaft furnace and Testing Equipment.

1. Construction material burning shaft furnace

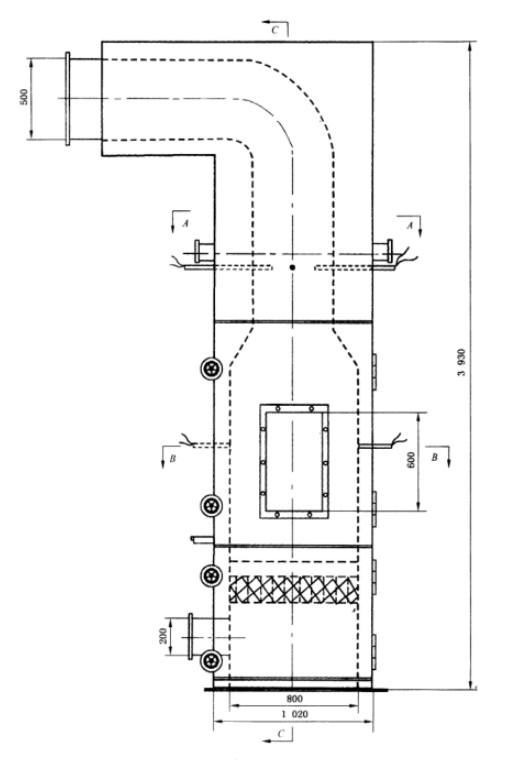

The building material burning shaft furnace is mainly composed of burning chamber, burner, test piece support, air steady flow layer and flue and other parts. Its overall dimensions are 1020mmX1020mmX3930mm.

1. Burning chamber

The burning chamber is composed of a furnace wall and a furnace door, and its inner space size is 800mmX800mmX2000mm. The furnace wall is an insulating interlayer structure, and its structural form. The furnace door is divided into upper and lower doors, which are respectively connected to the furnace body by hinges, and its structure is similar to that of the furnace wall. The two doors are closed with the furnace body by means of hand wheels and fixed screws. There are observation windows on the upper furnace door and the rear wall of the burning chamber.

2. Burner

The burner is placed horizontally in the center of the burning chamber, 1000mm from the bottom of the furnace.

3. Specimen support

The specimen support is a rectangular parallelepiped frame with a height of 1000mm, and the four sides of the frame are provided with screw rods for adjusting the installation distance of the specimen, and the frame is made of angle steel.

4. Air steady flow layer

The air stabilization layer is a square frame made of angle steel, which is set under the burner. Barbed wire is laid on the bottom of the box, and multiple layers of glass fiber felt are laid on it.

5. Flue

The flue of the burning shaft furnace is a square channel with a cross-sectional area of 500mmX500mm, and is located on the top of the furnace. The lower part communicates with the burning chamber, and the upper part connects with the external chimney.

6. Gas supply

In order to form a uniform airflow in the burning chamber, air is input at a constant rate and temperature through a 200mm pipe at the lower part of the furnace body.

2. Building material burning shaft furnace test equipment

The test equipment for building materials burning shaft furnace includes flowmeter, thermocouple, temperature recorder, temperature display instrument and furnace pressure test instrument, etc.

1. Flow meter

For the measurement of methane gas and compressed air flow, a flow meter with a precision of 2.5 and a range of (0.25~2.5) m3/h is selected.

2. Thermocouple

Flue gas temperature and furnace wall temperature are measured by nickel-chromium-nickel-silicon armored thermocouples with a precision of grade II, a wire diameter of 0.5mm, and an outer diameter of no more than 3mm.

3. Temperature recorder and display instrument

The temperature measurement is displayed and recorded by a microcomputer, and its test accuracy is 1°C. An electronic potentiometer with a precision of 0.5 grade that can be continuously recorded with a thermocouple or other suitable continuous recording instruments can also be used.

The test device for the flame retardant test method of building materials produced by Zhongnuo is also equipped with a temperature control system and a set of thermocouples with a diameter of ¢2.0 and a nickel-chromium armored thermocouple with a precision of II. The intelligent PID temperature control inspection instrument is matched with the K-type thermocouple. Its reading can be greater than 500°C. It has an auto save function. Materials that have passed the building material combustion furnace test and can pass the building material flammability test can be designated as flame-retardant building materials, which meet the

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now